Custom Beadlock Wheels 17

Finishing: Customized

Width: 12-16J

PCD: 130 mm, 120MM, 108 mm, 115 mm, 112 MM,

ET: 10MM, 15 mm, 18 mm, 20 mm, 50MM, 30MM, 35 mm, 40MM, 42 mm, 45 mm, 25 mm, 0mm

Material: Aluminum Alloy

After installation

Product Information

| Item | Monoblock/2 Piece/3 Piece/Forged Wheel; Carbon Fiber Wheel; Wire Wheel; Casting Wheel Or Others |

| Brand Name | GREX |

| Material | 6061-T6 Aluminum alloy |

| Size | 17-22inch/Customized as your requirements |

| Width | 7J~10J/Customized as your requirements |

| PCD | 130mm, 120mm, 108mm, 115mm, 112mm, 127mm, 100mm, 139.7mm, 98mm, 165.1mm, 114.3mm, 120.65mm, 143.1mm |

| ET | 10mm, 15mm, 18mm, 20mm, 50mm, 30mm, 35mm, 40mm, 42mm, 45mm, 25mm, 0mm |

| Color | Silver/Grey/Black/Bronze/Rose Gold/Gold/Custom as your request |

| Design | Custom design renderings within 48 hours |

| Warranty | Structure 8 year warranty |

| Certification | TUV/JWL/VIA/ TSE/ SFI /TS16949 |

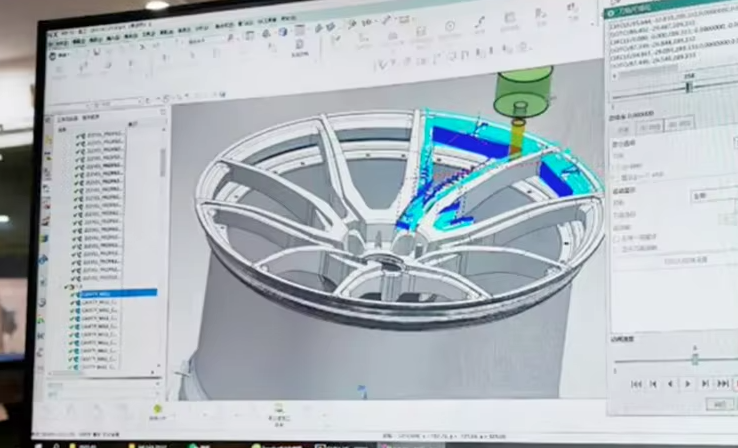

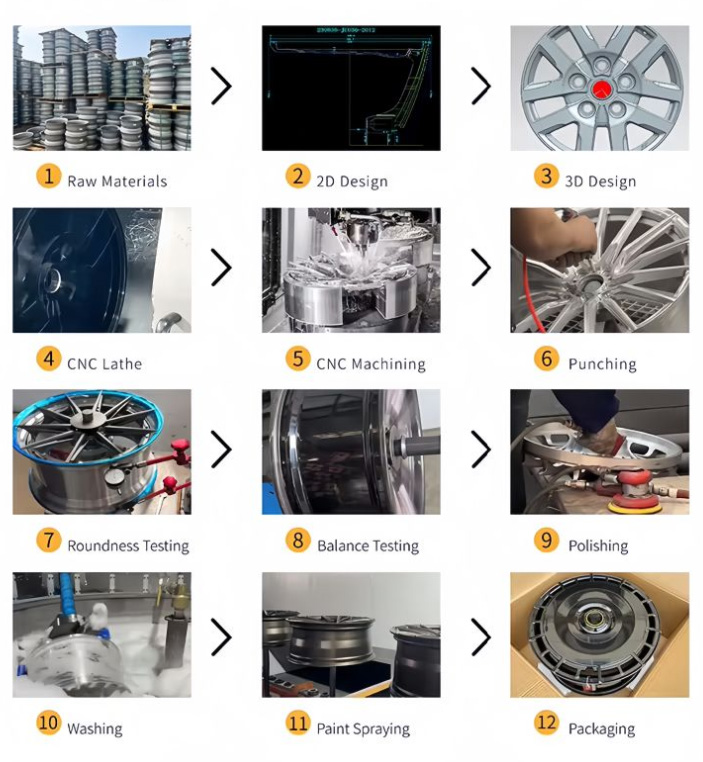

Manufacturing Process

Exclusive Customization

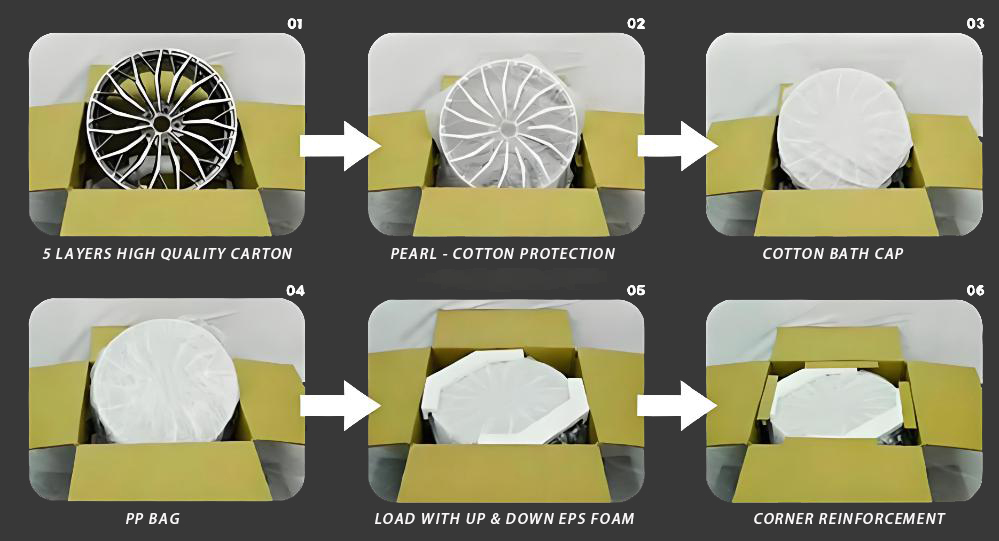

Product packaging

Shipment

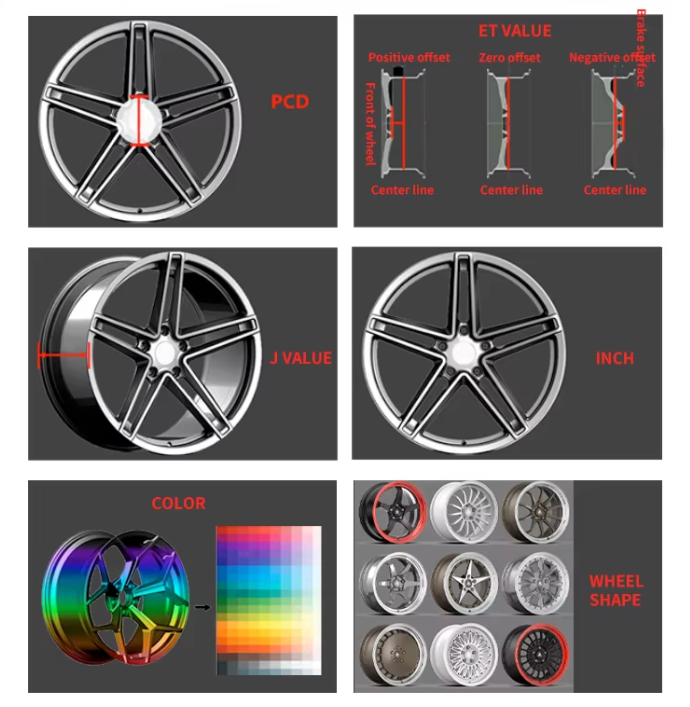

Alloy Wheel Specifications Explained

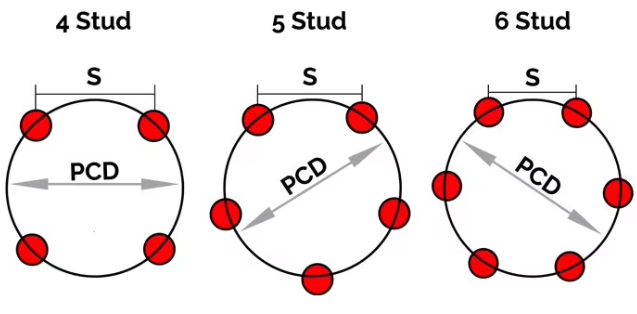

1, PCD (Pitch Circle Diameter) Explained:

This is the diameter of an imaginary circle drawn through the centre of the bolt holes. The PCD of the wheel should match the PCD that your car came with as standard.

PCD is measured in mm. e.g: 4x100 means the wheel has 4 bolt holes and the diameter of the imaginary circle through the bolt holes is 100mm. These details are shown in the 'Wheel Specifications' section on the main product page.

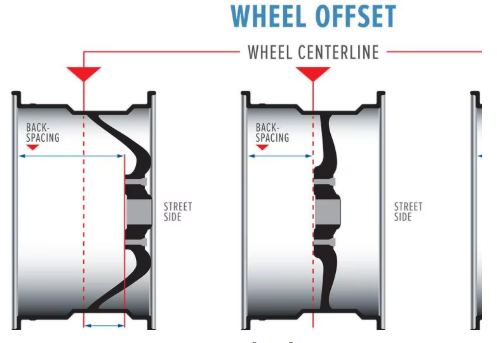

2, The Wheel Offset (ET) Explained:

The offset determines how far under the arch or how far towards the outer arch a wheel will sit. Each car has its optimum offset and a range within which the offset can be for the wheel to fit the car properly.

If the offset is too low for the range allowed, the wheel could stick out from the side of the car, if too high from what it should be the wheel may catch on the suspension or bodywork as it will be too far under the car.

This is due to the fact that if you put a wheel on your hub with a higher offset than before, the wheels bolting face will have to move further under the car to meet the hub, in extreme cases causing the wheel to sit too far under.

If you take a wheel and cut it in half and draw a line down the centre of the width of the alloy wheel the offset will be the distance between the back face (mounting face) of the wheel and the centre line that you have just drawn.

The offset is commonly shown as the letters ET followed by a number, eg: ET49. The offset is always measured in mm and can normally be found stamped on the back of the wheel or behind the centre cap (if fitted).

3, Wheel Width & Diameter:

The alloy wheel size is shown as follows: Wheel diameter x Wheel width - e.g: 15 x 6.5J

The width is the section between the tyre mounting flanges on the wheel / The diameter is the overal diameter of the wheel.

4, Wheel Centre Bore and Spigot Rings Explained:

This is the diameter of the centre hole in the back of the wheel. It is crucial that the centre bore of the wheel locates properly on the lip on the hub of the vehicle to get a perfect fit. Most wheels work on a spigot ring locating system because most wheels have a centre bore bigger than the size of the hub lip allowing them to fit a wider range of cars. A spigot ring is fitted into the back of the wheel with an outer diameter the size of the centre bore, and an inner diameter the size of the hub lip to allow the wheel to be correctly located onto the hub and to fit tightly onto the vehicle for safety and comfort.

There are wheels that are hub-centric i.e. the wheel is manufactured with a centre bore to fit precisely onto a specific vehicle and in these cases we would not supply spigot rings as they would be unnecessary.

If the wheel does not locate onto the vehicle's hub assembly correctly it will cause a vibration on the steering wheel and can lead to bad wear on the tyres and bearings so if spigot rings are provided you MUST use them.

Our Certification

At Forgex Wheel, we are committed to delivering the highest quality forged wheels, and our products are backed by a range of global certifications that demonstrate our expertise and reliability.

We proudly hold certifications such as TUV, VIA, DOT, JWL, IATF 16949, ISO 9001, ISO 14001, ISO 45001, REACH, and ROHS, ensuring that our forged wheels meet the strictest industry standards for performance, safety, and environmental responsibility.

These certifications reflect our dedication to manufacturing wheels that are not only aesthetically superior but also durable, safe, and environmentally friendly, providing our customers with exceptional value and peace of mind.

Product type

INQUIRY

Categories

Latest News

Contact Us

Phone: +8615883654752

E-mail: Sales@grexwheels.com

Whatsapp:+8615883654752

Add: 81 Dongsheng Sub-district,Shuangliu District, Chengdu City, Sichuan Province, China